DIGITAL GRAPHICS THE 日本 WAY

Fukui Byora / UBC Engineering International Co-op Exchange | 3DCG Designer

Fukui Byora, a cold-forming company that specializes in creating small mechanical parts, hires international co-op students in collaboration with UBC engineering every year in various fields. I was hired to create 3D digital graphics to be used for the company’s website and other third-party outlets. Content ranged from creating medical equipment such as an endoscope and a prosthetic leg in 3D space and finding creative ways to feature small metal objects in a big way.

During my 8 month internship, I worked on creating digital marketing assets for their electronic parts, medical equipment parts, and finally animation assets to be used in a marketing video.

The biggest challenge was adapting to 3ds MAX from using Lightwave and also conversing in Japanese with my supervisor for tips and instructions.

Programs used: Autodesk 3ds MAX, Adobe Creative Suite.

TIMELINE OF MY INTERNSHIP AT FUKUI BYORA

The usual 1-year internship was shortened to 8 months due to scheduling conflicts. I was brought on to create website graphics, a website animation to be used at an advertisement portal site and an original animation to be used by the marketing team.

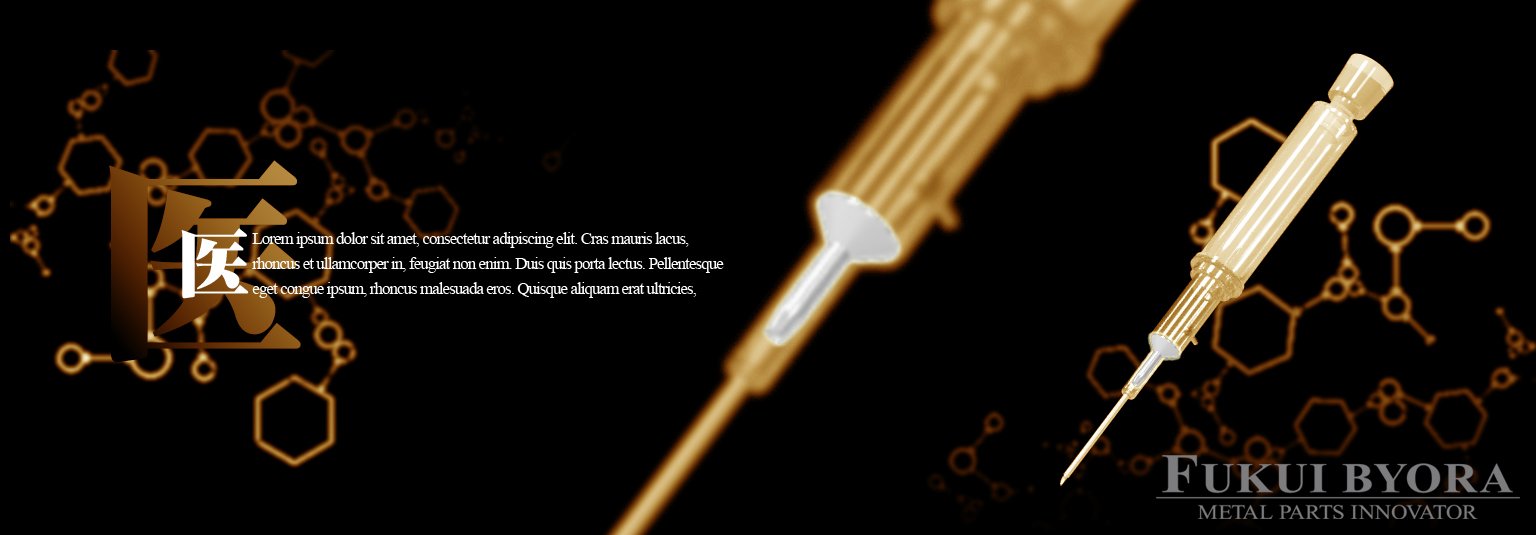

PHASE 1: USE EXISTING MODELS TO CREATE GRAPHICS

To get used to creating 3D graphics in Autodesk 3ds MAX due to my preferred program at the time being NewTek Lighttwave, I was tasked with taking existing 3D models of various electronic objects and using those to create banners to be used for the company website.

CONCEPTS AND DRAFTS

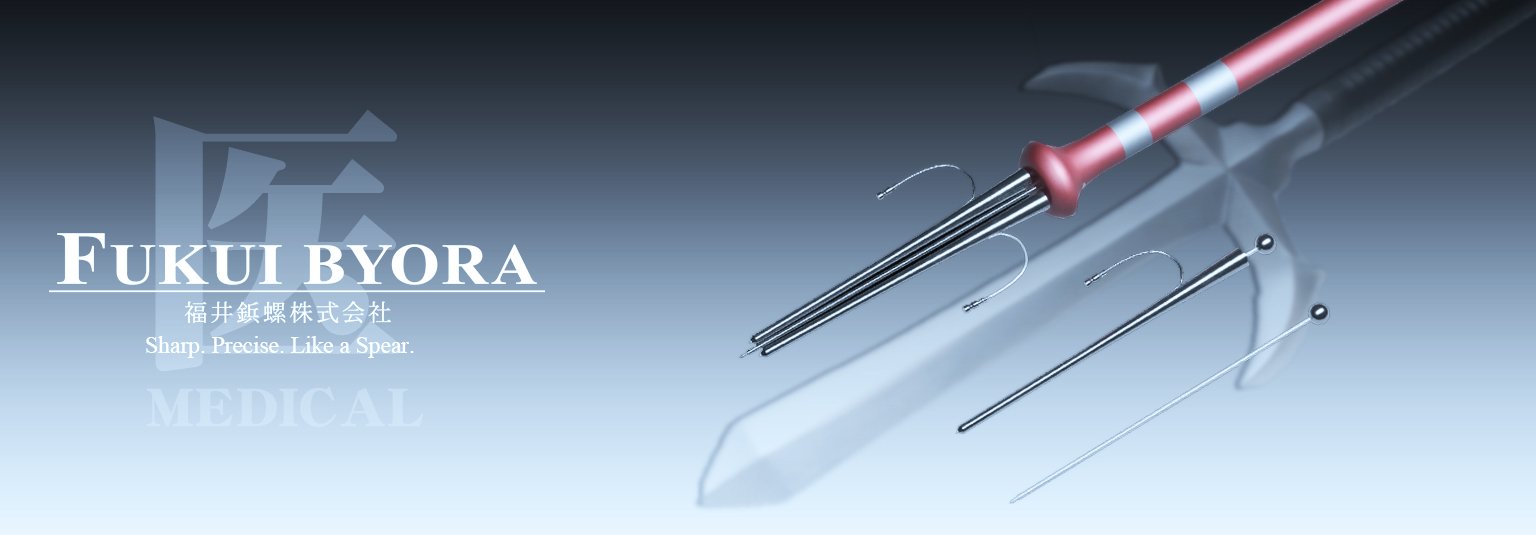

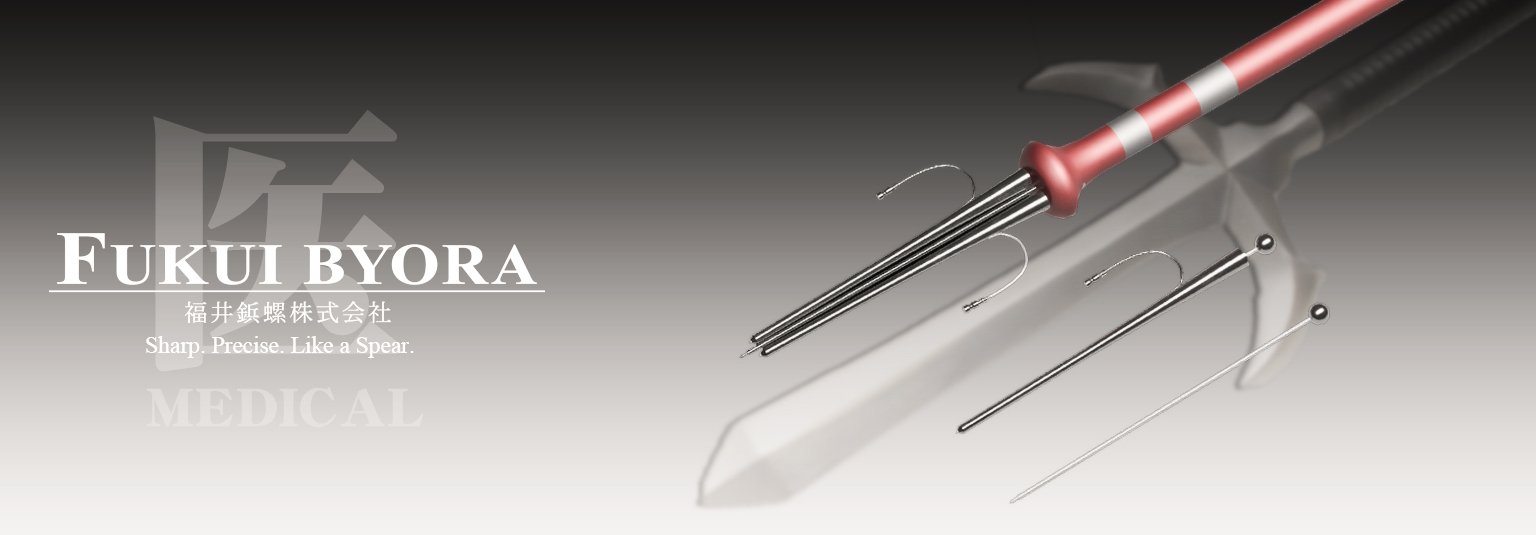

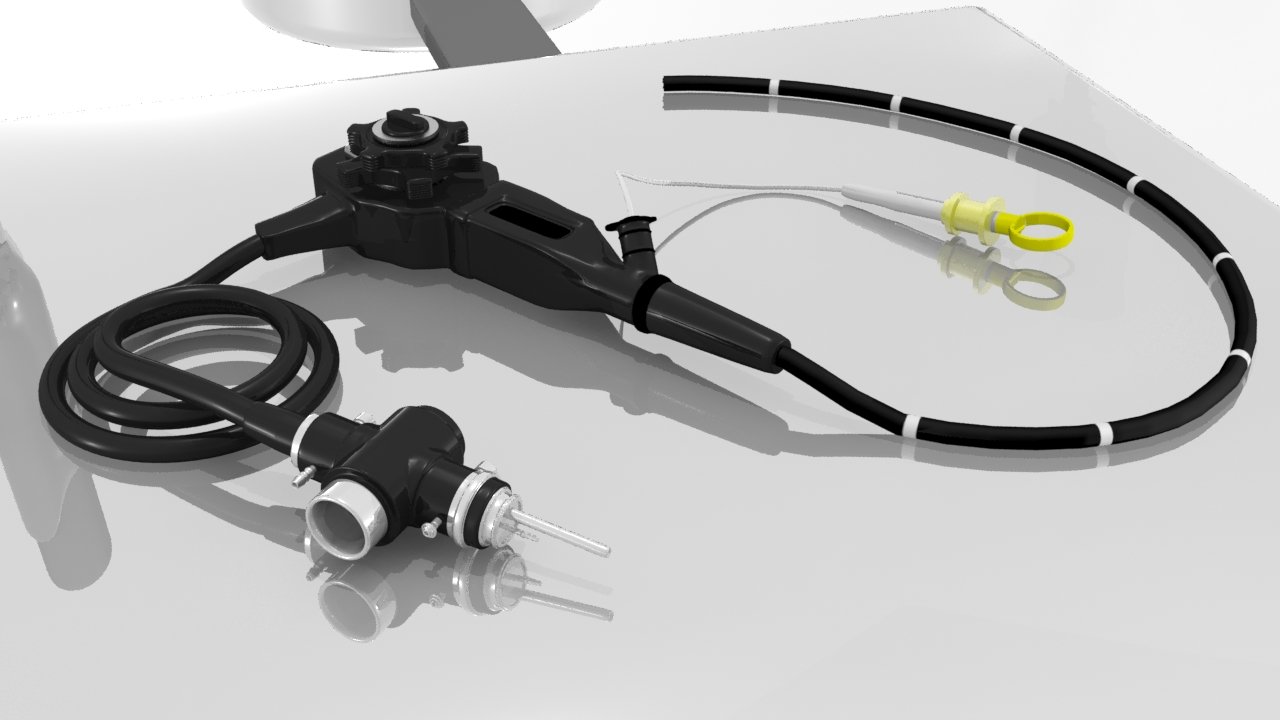

PHASE 2: REAL-WORLD OBJECT MODELLING

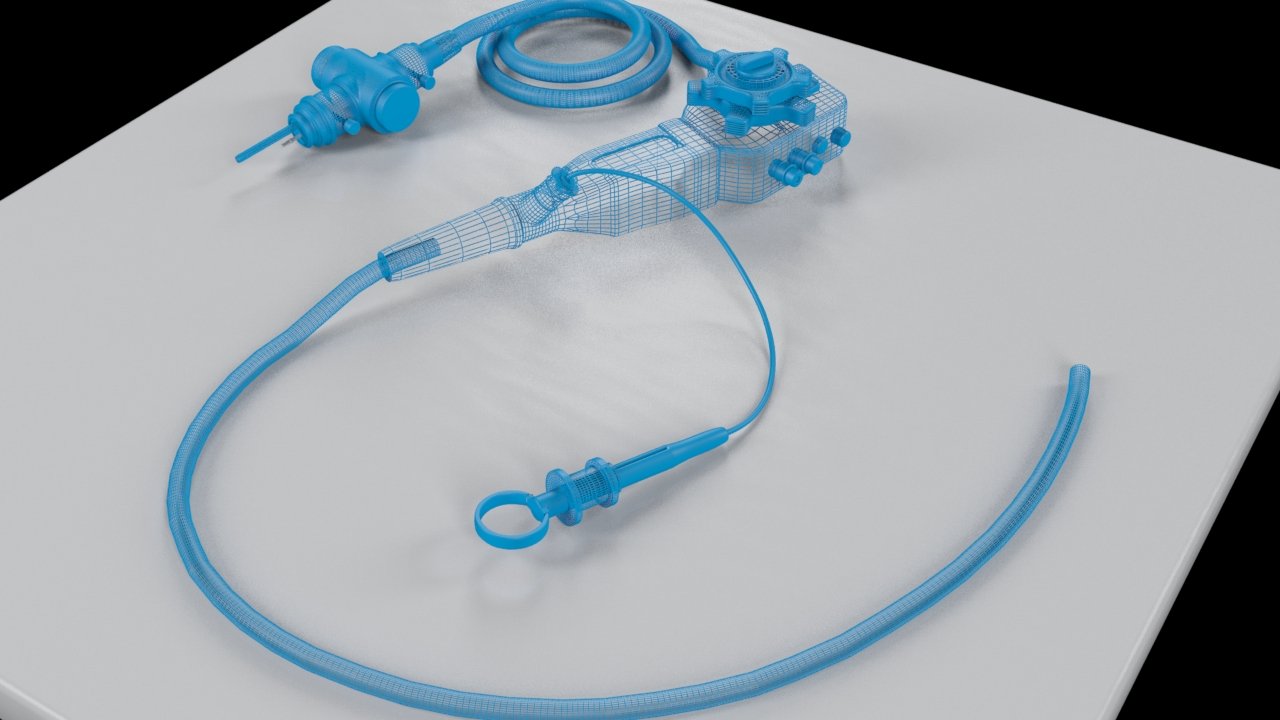

After getting used to modeling in 3ds MAX, I was next tasked with creating new models to add to the 3d model database for future usage including an endoscope and a prosthetic leg. These models were to be used in phase 3 of my internship where I would use it in a 3d animation.

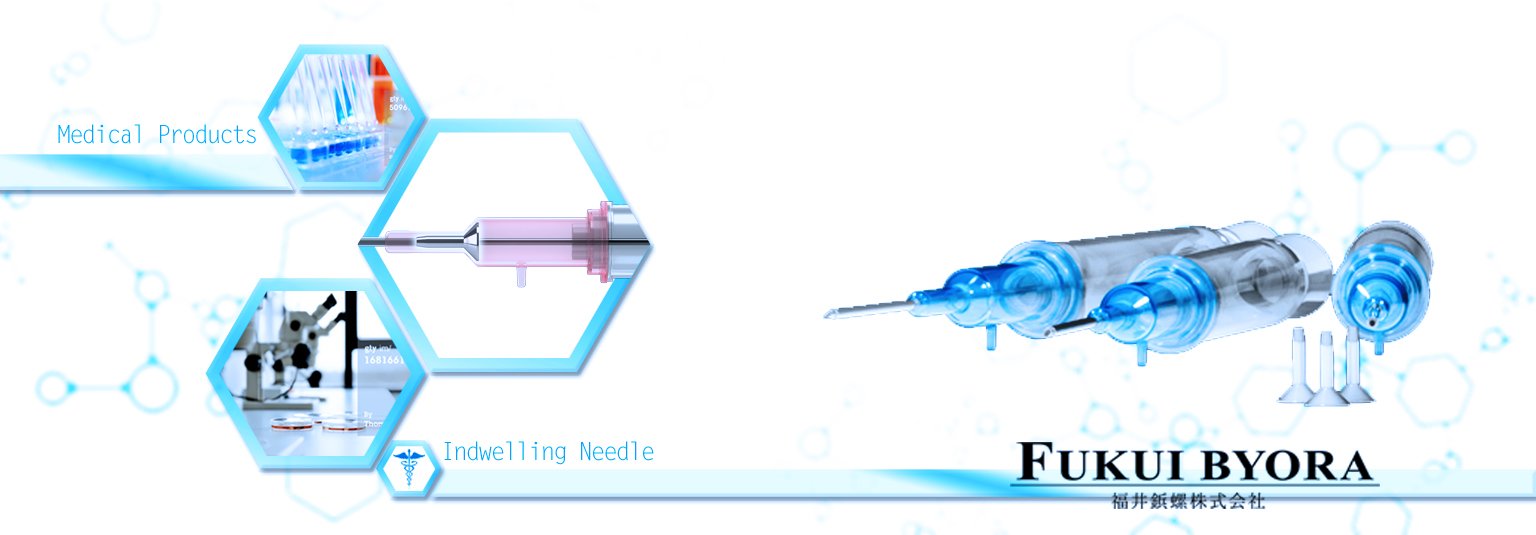

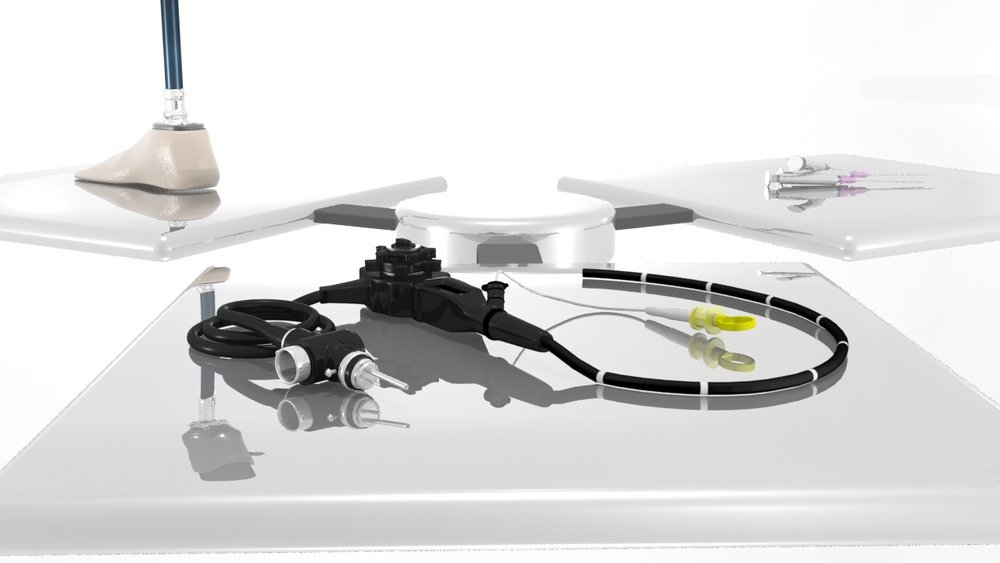

PHASE 3: PUTTING IT ALL TOGETHER

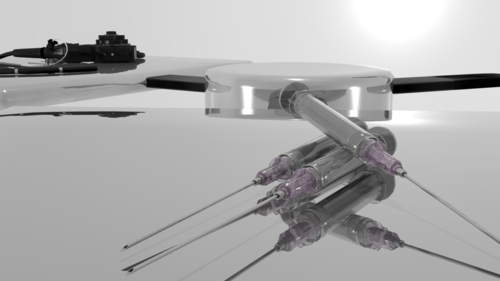

Now that all the pieces are created, it is time to animate them. Given the direction from my manager, I produced short animations and stills that would accompany other images and footages in the final footage edited by the marketing team. I was responsible for featuring the medical products the company’s cold header products were used in. Syringes, endoscope and prosthetic legs were featured and utilized a x-ray like effect to show where the parts were used in.

PHASE 4: ANIMATING SMALL PARTS IN A BIG WAY

One of the more important projects during my time at Fukui Byora was creating a GIF banner on ipros.jp. A Japanese business listing website that is well renowned and a go-to website for many businesses. I took the many models of the minuscule parts the company produces and created an animation showcasing the company’s app which is can be used by customers to view the company's products.